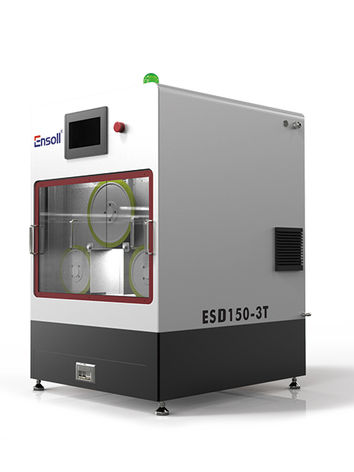

ESD150-3T

ESD150-3T Diamond Wire Saw Cutting Machine

This diamond wire loop tabletop cutting equipment is a high-precision cutting tool designed for laboratories, research institutions, and small-scale processing workshops. Using diamond wire technology, it's suitable for the precision cutting of various hard and brittle materials. Characterized by high precision, efficiency, and user-friendly operation, it's an ideal choice for scientific research and small-scale production.

Capable of cutting a variety of hard and brittle materials, including silicon wafers, sapphire, ceramics, glass, stone, composite materials, and more.

What you get

- Excellent cutting quality

- Low acquisition costs

- Simple maintenance

- Short lead time

- 12 months quality warranty on machines

- Free trial cutting services

- Worldwide support from experienced and competent staff

Characteristics

High-Precision Cutting:

The cutting precision is ±0.05 mm, with a surface roughness as low as Ra 0.5 μm, meeting the demands of high-precision processing.

Suitable for cutting ultra-thin materials, with a minimum cutting thickness of 0.1 mm.

Multi-Functional Applicability:

Capable of cutting a variety of hard and brittle materials, including silicon wafers, sapphire, ceramics, glass, stone, composite materials, and more.

The wide cutting thickness range, from 0.1 mm to 50 mm, caters to different material requirements.

High-Efficiency Cutting Speed:

The cutting speed can reach up to 20 mm²/min, significantly improving experimental and production efficiency.

Automated cutting mode reduces manual intervention and enhances consistency.

Compact Desktop Design:

The equipment features a small footprint of just 0.5 m², making it ideal for laboratories and small workshops.

The user-friendly interface supports one-click operation, ensuring ease of use.

Low Consumable Costs:

The diamond wire has a long service life, with a single wire capable of cutting over 1000 meters of material, reducing consumable costs.

The equipment is easy to maintain and has low operating costs.

Technical parameters

Dimensions (L x W x H):

650mm x 750mm x 980mm

Weight:

230 kg

Work Area:

150 mm x 150 mm

Feed Speed:

0.1-10 mm/min

Cutting Speed:

0-35 m/s

Max. Cutting Stroke:

150 mm x 150 mm (Y-axis x Z-axis)

Maximum Cutting Size (L x W x H):

150 mm x 150 mm x 150 mm

Drive Type:

Servo motor

Operating Voltage:

220 V

Maximum Workbench Load:

10 kg

Total Power:

1.8 kW (estimated)

Wire Length:

1470 ± 5 mm (tentative; final length to be confirmed after test cuts)

Wire Wheel Diameter:

Two 180mm wheels and one 230mm wheel (with a single slot)

Wire Diameter:

0.35 mm